Services

Have a question about our products, or want to collaborate on your project?

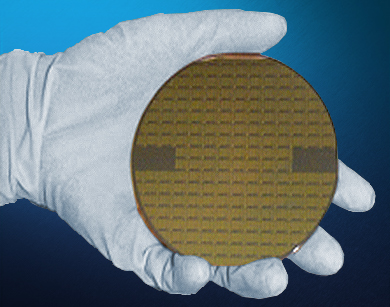

Foundry Services

10 Production Scale Metal-Organic Vapor Phase Epitaxy Tools

- 5: Veeco K475 TurboDisc Reactors – 64 x 2", 32 x 3", 15 x 4", 7 x 6"

- 5: Veeco E400 TurboDisc Reactors – 32 x 2", 16 x 3", 12 x 4", 4 x 6"

GaAs & InP material systems growth capabilities

- GaAs: GaInP, AlGaInP, AlInP, AlGaAs, GaInAs, GaInNAs

- InP: GaInAs, GaInAsP, GaAsSb, AlGaInAs

Advanced wafer processing (Ge, GaAs, InP & Si) capabilities at R&D scale

- Class 1,000 clean room

- Wafer bonding: direct wafer-to-wafer bonding, metal bonding, adhesive bonding

- Wet etching & Dry etching (RIE & Plasma cleaning)

- Wafer thinning (lapping, polishing), CMP

- Evaporation of thin films, both metals and dielectrics

- Photolithography with front-to-back alignment

- RTP (Rapid Thermal Processing)

Characterization Capability

- HRXRD, PL, Reflectance, EL, ECV, DEKTAK

- Spectral Response, LIV, SEM, EL, AFM

Knowledgeable Staff

- 9 engineers : 5 with PhD's in MOVPE/Device Physics, 3 Associate Technical Fellows

- Extensive experience in optoelectronic materials and devices

Packaging

Spectrolab operates a world-class packaging laboratory for prototype assembly and test. The engineers of the packaging team will work with you to custom design photodiodes, and laser fiber packages to meet your specific needs. We have the capability to inspect and test the package during and after assembly to meet the Bellcore standards. Finally, Spectrolab has state-of-the-art modeling tools and the expertise to perform thermal, mechanical, vibration and optical analysis.

Spectrolab's state-of-the-art packaging laboratory includes the following equipment:

- Die Attach Equipment:

- Manual epoxy die attach

- Oven for temperature curing of epoxy

- UV curable adhesives dispense system with the UV lamp for primary cure and UV oven for final cure Manual eutectic die bonder for installation of components using alloy material

- Wire Bonding Equipment:

- Fiber Coupling Equipment:

- Microscope for visual inspection of fibers

- Interferometer for mapping of fiber terminations

- Splicer for fiber splicing and lens formation

FAA Repair

Spectrolab is dedicated to providing you with complete service and support for all your Spectrolab Nightsun, StarSun and Starburst Searchlight products. Regular maintenance is needed to optimize Searchlight system performance. Our highly skilled & FAA Certified technicians are dedicated to provide the most exceptional service and quality in the industry.

Spectrolab's certified FAA Repair Station 14 CFR, License number L9SR877X is also European Aviation Safety Agency approved, EASA Part 145 (EASA 145.6676).

Engineering Services

Spectrolab, A Boeing Company, is leveraging over 65 years of industry leading space power experience to ensure our customers have reliable and safe access to space. We are opening our engineering talent with our best and brightest at your fingertips, to ensure a successful mission. The following key design and analysis tools available to industry:

Mission power analysis

- An analysis for any orbit or interplanetary mission

- Includes a radiation analysis

- Can be done for any phase of the mission (BOL, EOL, mid mission, etc..)

Electro-Static Discharge (ESD) Analysis

- ESD events on solar arrays are a known and significant failure mode

- SPL will ensure design survivability for a given mission

Magnetic Moment Analysis

- Magnetic interference with payloads or the earths magnetic field can be minimized via special layouts and design features

- Cancellation across an axis or a center of gravity

Survivability and Reliability Analysis

- Confirming use of solder/weld/other assembly processes confirmed vs. thermal-mechanical stresses for the mission

- Atomic Oxygen analysis and design protection

- FMEA (Failure mode effects analysis)

- Reliability analysis to ensure compliance to reliability requirements

Acceptance Test & Qualification Test

- Leverage SPL's heritage to avoid costly qualifications and acceptance test procedures!